Would you like to get to know us and our solutions in person? Then visit us at international trade fairs and congresses. We look forward to see you!

Current datesPowertrain

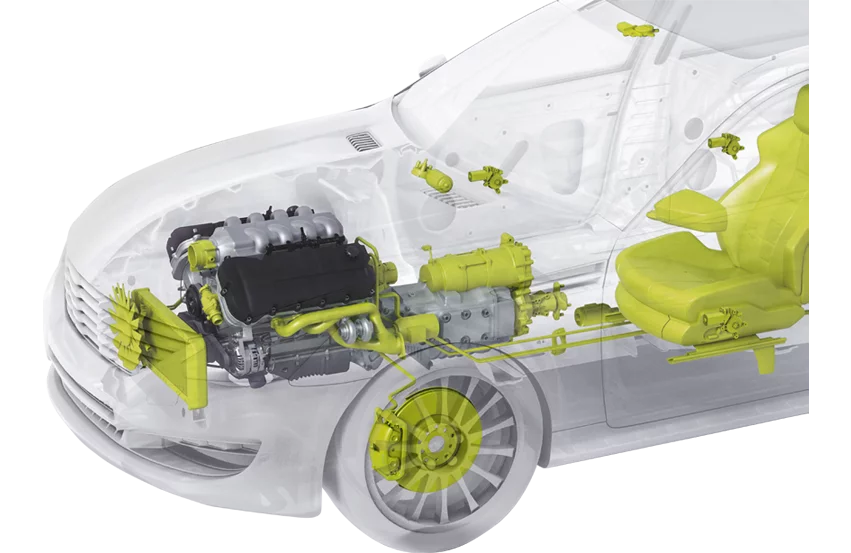

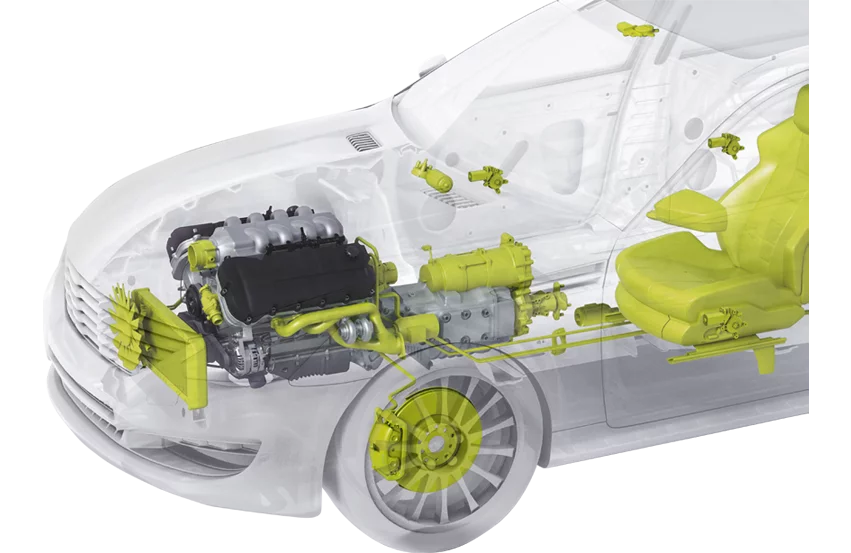

Overview of our powertrain components

Powertrain components made to the highest standards

A vehicle's drivetrain is a highly complex system which requires a large number of different components to work together seamlessly. However, the requirements that individual functions place on these materials are extremely diverse. While service life, efficiency and speed stability should be as high as possible, power loss must be minimized. Low weight and minimal tolerances are just as important as lightweight materials, great temperature and corrosion resistance, and good tribological properties. If the components are in the oil circulation system, then technical cleanliness is another important property. Last but not least, the products need to be manufactured ready to install and within a competitive cost structure.

High-quality materials are the solution

Our customized materials are the answer to all of these challenges. Our carbon brushes are made-to-order products we design specifically for customer projects by getting involved early on, choosing from a broad range of materials and applying our decades of development expertise. You can trust in our expertise in the “mechanical carbon” area, and rely on the certified manufacturing processes we employ to fulfill our quality mission under our zero-defect philosophy.

In the sintered technology sector, we impress by choosing the right manufacturing processes, implementing line concepts in our process design, and developing optimized handling concepts in-house for process sequences. Another of our strengths is application-specific material development, as is developing “green part” machining for sintered components. Last but not least, we offer competent material testing from our certified in-house testing laboratory.

Your advantage: everything from a single source

With Schunk, you have a partner who can handle all production processes. We offer excellent materials expertise in the carbon and MIM areas, as well as outstanding production knowledge in the sintered components area. We also offer consistently automated production processes, net shape design and ready-to-install products that achieve significant noise reduction, for instance, thanks to custom-tailored material and geometry solutions.

Carbon brushes, mechanical carbon components and sintering for many different components

Our developments are used in many powertrain components. We manufacture Schunk carbon brushes, for example, for starters, fuel pumps, and ETC motors. We also provide rotors and vanes that are used in vacuum pumps for brake boosters. Alongside our bearings for exhaust systems and graphite injection molded parts for coolant pumps, we offer a full portfolio of mechanical carbon components to meet your needs. In addition, we develop hybrid components made of carbon and sintered metal – a unique product range not offered by any of our competitors.

We also provide sintered technology solutions in three types of manufacturing, depending on quantity and complexity:

Axial pressing, MIM and 3D printing. Our components are used in valve drive components, sprockets, toothed belt wheels, actuator parts, parts for water and oil pumps, brackets for fuel injectors, camshaft adjusters, sensor wheels for camshafts, rotors and stators for camshaft timers, sprockets for balance shaft drives and components for planetary gears and parking brakes. All of our products combine outstanding quality with a long service life and low wear. Schunk products help keep engine performance stable throughout the entire engine service life.

Do you have any questions about our Powertrain Components?