Schunk Technology in Operation at Pier 400

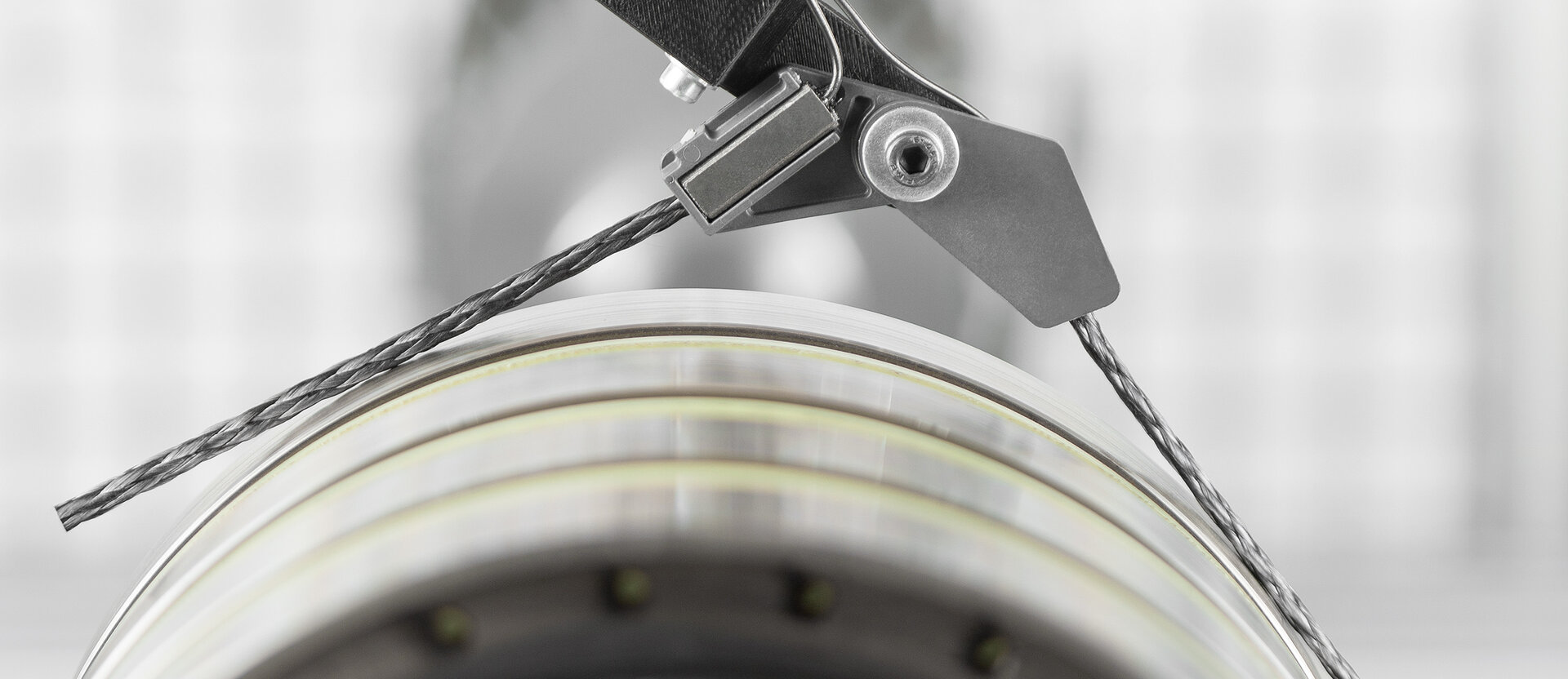

At Pier 400 in the Port of Los Angeles, one of the world’s busiest container terminals, a new high-performance charging system is now in daily use. In collaboration with Kalmar and APM Terminals, Schunk Transit Systems has implemented two Inverted Pantographs SLS201.401 to support the first fully electric straddle carriers in North America. The system enables automated, high-current charging (up to 1,200A)—ideal for demanding port environments with tight schedules and continuous operation.