Friedrich Eisenkolb Accredited Testing Laboratory

Competent, fast and flexible

General

More than 60 years ago, our eponym, Prof. Friedrich Eisenkolb, laid the foundation for our powder-metallurgical test laboratory in Thale, Germany. We carry out physical, mechanical-technological and analytical testing at metallic and powder metallurgical materials as well as testing of metal powder and testing of technical cleanliness.

Our team of 9 employees guarantees technical competence at the highest level and ensures promptness and flexibility for the solution of complex material-testing tasks.

Our laboratory is a certified training organization for material inspectors.

Mechanical-technological testing

- Tensile test at room temperature and up to a maximum of 1.100 °C, bending test, compression test

- Determination of Charpy and ASTM notch impact strength; RT to - 196 °C

- Brinell, Vickers and Rockwell hardness testing; small-load hardness, hardness-displacement-curves, micro-hardness testing

- Technological tests on components in accordance with requirements

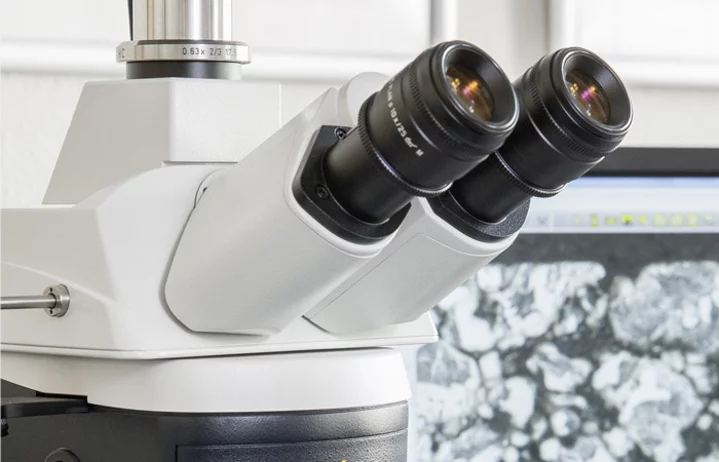

Metallography

- Macro and micro analyses

- Sinter materials

- Castable materials

- Fe materials low-alloy to high-alloy

- Non-ferrous metals

- Heat-treated parts

Damage inspections:

- Digital image analysis

- Determination of phase fraction

- Particle-size analyses

- Coating thickness measurement

- Graphite size determination in accordance with DIN ISO 945

Powder testing

- Determination of grain-size distribution with a laser grain-size analyzer (0.01µm bis 3500µm)

- Determination of tap density

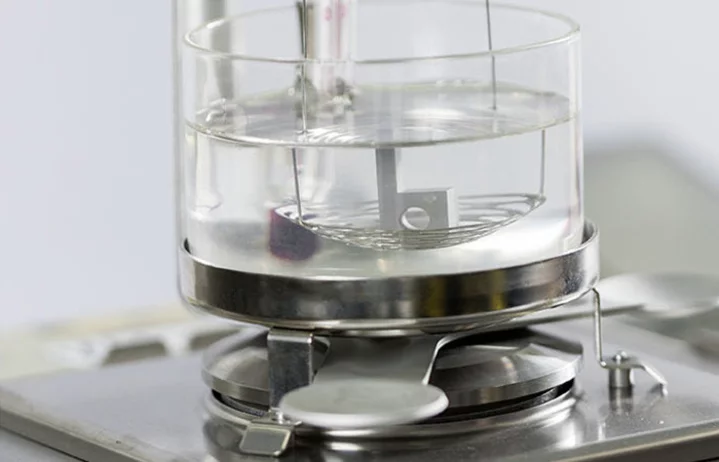

Test of technical cleanliness

- VDA-Guideline 19 Part 1 (Test of technical cleanliness – particle contamination of functionally-relevant auto parts),

- ISO16232 (Road vehicles – Cleanliness of Components of Fluid Circuits)

- In accordance with plant standards of automotive manufacturers and suppliers

Physical testing

- Density determination: immersibility density

Non-destructive material testing

- Surface crack testings

Chemical analysis

- Analysis of compact samples with OES

- Determination of carbon and sulfur with CS- analyzer

- Determination of oxygen and nitrogen contents in metals

- EDX analyses

Scanning electron microscopy

- Fracture surface analyses

- Damage analyses

- Microstructure analyses of metallic and non-metallic materials

- Length measurement in micro range

- EDX analyses

- Element distributions (line scans, mappings)

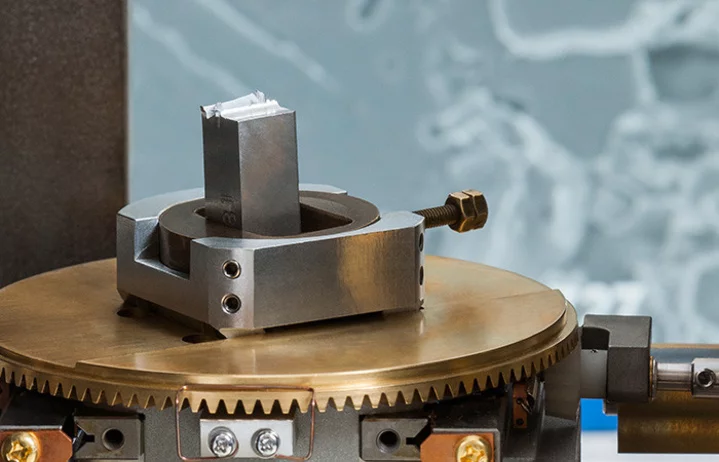

Metal-powder blanks for prototype production

- Presses with floating dies

- Diameters of 58, 80, 100 and 130 mm

- Maximum height 42 mm (depending on density)