Way ahead of standard materials for rotary vanes

Dry-running rotary vane vacuum pumps are often used when a clean, oil-free vacuum is required in industry. For example, in the chemical industry, paper manufacturing, pharmaceutical industry, food processing, in hospitals and in the packaging industry. Here, the rotary vanes are permanently exposed to high loads, which can lead to rapid wear. With innovative carbon-based materials, service intervals and service life can be significantly extended.

Lifetime of the rotary vane determines the service interval of the vacuum pump

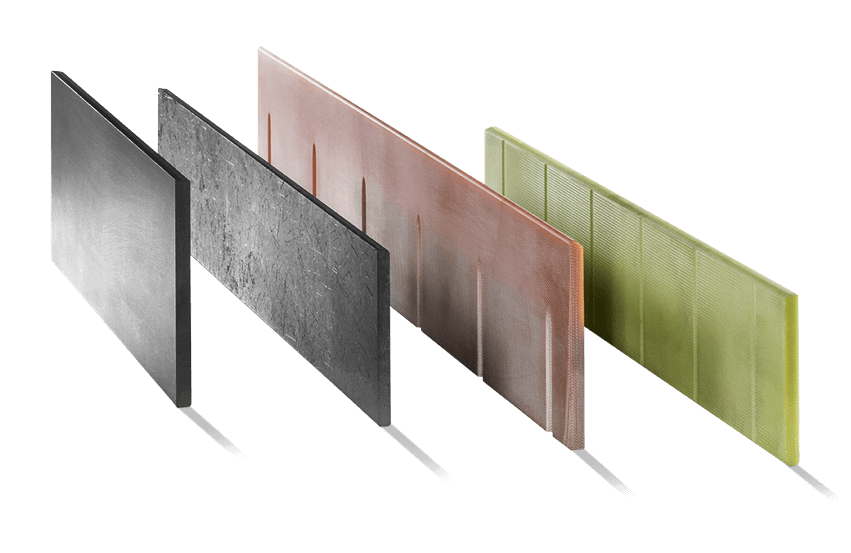

In dry-running rotary vane vacuum pumps, the service intervals of the machine are determined by the service life of the vanes. By using innovative materials, Schunk has succeeded in significantly extending these intervals. The key to this optimization lay in years of developing a carbon material that is both self-lubricating and durable. The typical pump design consists of several vanes inserted into a slotted rotor. During pump operation, the vanes contact the rotor and housing and therefore require self-lubricating properties at both contact points.

An additional challenge, depending on the application and geographic region, is the humidity of the vacuum medium. Commonly used polymer-bonded vane materials swell in high humidity, which causes dimensional changes and can lead to increased wear rates, pump failures and assembly problems.

MarathonCarb™ for rotary vanes in vacuum pumps lasts up to three times longer

Low wear, no swelling: Schunk's experts have succeeded in developing carbon materials for rotary vanes that meet highest requirements. MarathonCarb™ is a self-lubricating vane material that minimizes wear on the sliding flanks (scour) as well as vertical wear and does not swell when exposed to humidity. Both on Schunk's own pump test benches and thousands of times in industrial use, vanes made of MarathonCarb™ have been able to achieve service lives and thus service intervals of over 30,000 hours. They thus offer up to three times the service life of other commercially available vanes and help to reduce maintenance costs.

You have further questions about our rotary vane material MarathonCarb™? Feel free to use our contact form.