Advantages when charging your logistics trucks

Strengths of the underbody solution compared to the plug-in

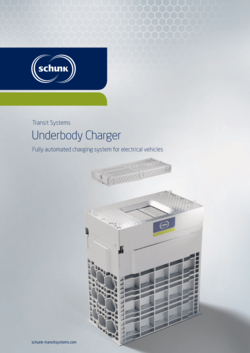

The fully automatic underbody loading system is space-saving, simple and safe. It complies with DIN EN 61851-23-1 and ISO15118 and meets all relevant design standards and basic safety regulations. To ensure a high system voltage, the contact systems are designed to be particularly safe and reliable. This includes protection against accidental contact, the prevention of electric arcs and unwanted heating as well as fused charging sequence control. There are further advantages compared to a plug-in solution:

-

Up to 1 megawatt charging power - resulting in shorter downtimes and around ten charging processes on one contact system per hour

-

Space-saving - no charging stations required in the loading depot

-

Error-proof - no manual operation, no charging cables

-

A hands-free alternative to the MCS (Megawatt Charging System)

-

Secure connectivity - integrated vehicle detection system and integrated parking tolerance compensation +/- 60 mm

-

Easy to retrofit - as a passive module, the interface can be easily and cost-effectively integrated into the logistics truck

Fully automated charging system for electrical vehicles