Advantages

Ceramic processing from Schunk includes:

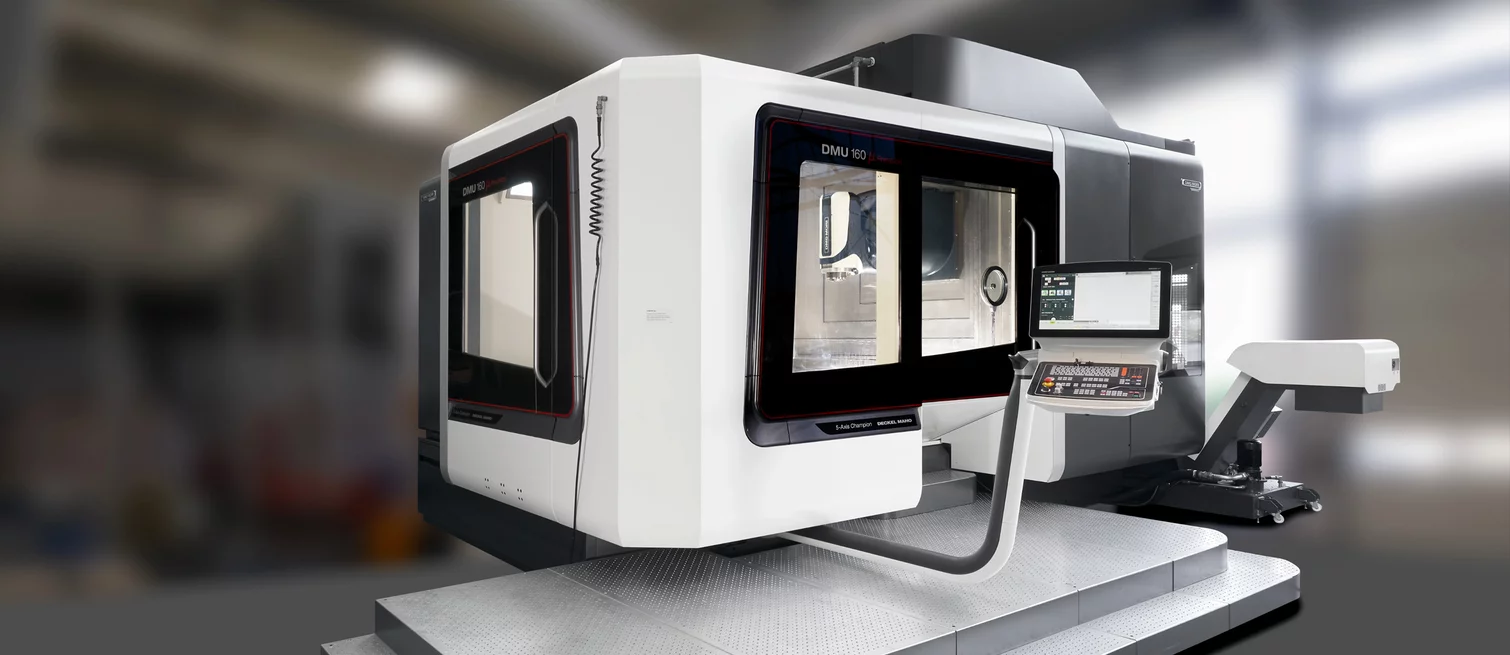

- Five-axis CNC grinding (RA<0.1 and flatness <5µm) for ceramic components of various sizes (from 30 x 30mm to 1m x 1.8m x 0.7m)

- Surface grinding (RA<0,3) for ceramic components up to 3m x 1m

- Cylindrical grinding - internal as well as external

- Wire EDM & Die Sinking EDM (EDM "Electrical Discharge Machining"/ Micro EDM) components up to 2m length and 430mm diameter

- Green milling

- Cutting

- Lapping and polishing (RA<0,1)

- Laser machining & laser marking (RA<0.8) as the most precise, efficient and reliable way to machine ceramic (Tolerances better than 10µm depending on component dimensions)

Advantages

Coating & Plating at Schunk Technical Ceramics:

- Nickel plating / Nip plating (50μm)

- CVD-SiC plating (high strength with up to 2mm thickness, layer thicknesses from 50μm to 2000 µm, crystal sizes from 1-20μm)