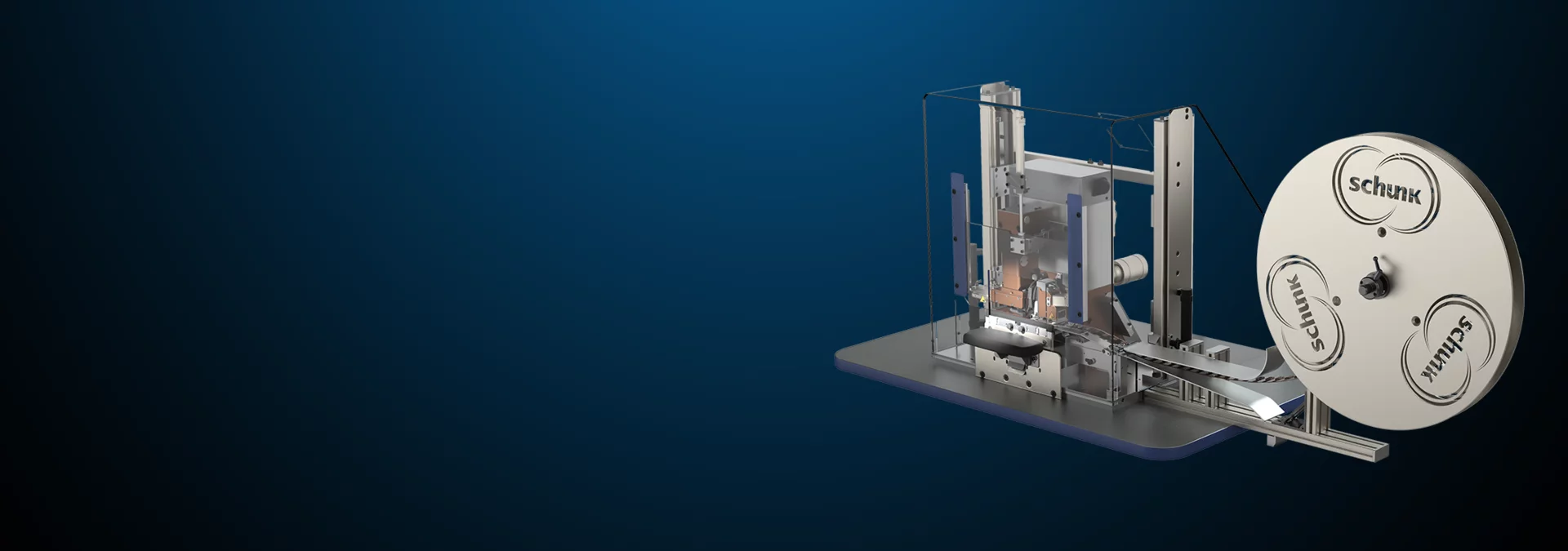

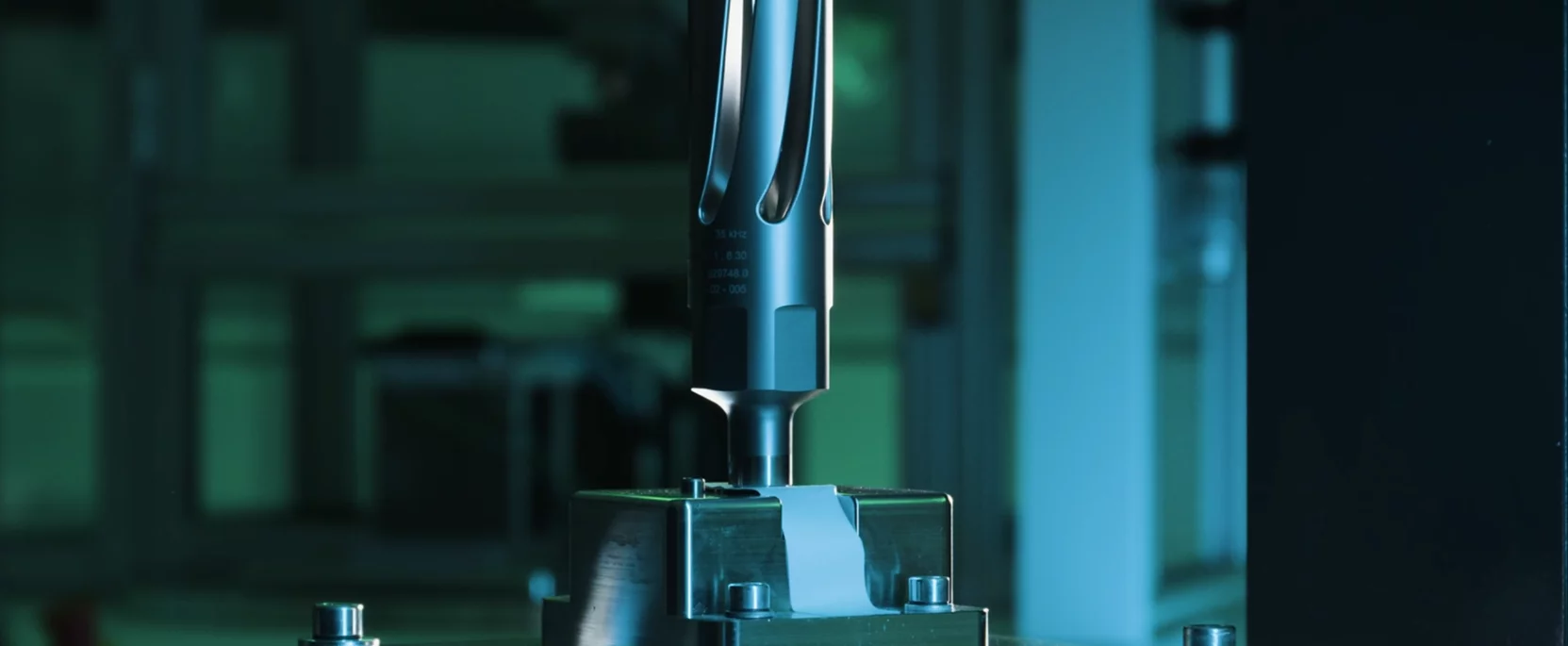

Wire Harness

In the automotive, construction, and appliance industries, connection technology is essential for durable and secure wire harnesses. Schunk Sonosystems offers precise ultrasonic metal welding for cross-sections from 0.08 to 200 square millimeters – ideal for high-current contacts and complex wire connections. Learn more about our solutions for your industry!