Safely dissipate shaft voltage

Many transport companies can tell you a thing or two about it: Suddenly, metros or trains are at a standstill due to damaged engine or transmission bearings. Such breakdowns are not only annoying, but above all expensive. The cause are often vagrant shaft voltages that discharge in the bearings and cause lasting damage. Shaft grounding systems made of infiltrated carbon fibers can provide a remedy, reliably dissipating voltages and protecting against bearing damage.

From subways to high-speed trains - we know from experience: In the rail market, there are many vehicles with inverter-controlled electric motors that have a problem with shaft voltages. And the impact of this voltage is great. Our customers are not only struggling with damaged motor and gearbox bearings. In some cases, we even found that the viscosity of the lubricants had changed to such an extent that there was no lubricating effect at all. But all problems have one thing in common: they cause costly unscheduled train downtimes and high maintenance costs. But what can be done to safely dissipate vagrant shaft voltages and extend the service life of the vehicles? This is a question that we at Schunk have been dealing with since 2013.

The German public transport companies in Karlsruhe and Dessau have also been affected by these problems.

Read why both companies can now rely on the performance of its vehicles again in our reference report.

Download Reference Report

Two grounding solutions for all requirements

It is clear that it is almost impossible to develop one standard solution. Because: No two trains are the same. The number of variants of drive units and combinations of motor and gearbox is too large. In order to be able to offer our customers the perfect solution for their requirements, it is also necessary to take into account the demanding operating conditions under which a grounding solution should function reliably. These include vibration shocks of up to 100 g, the alternating rotation of the shaft and influences from different media such as water or oil.

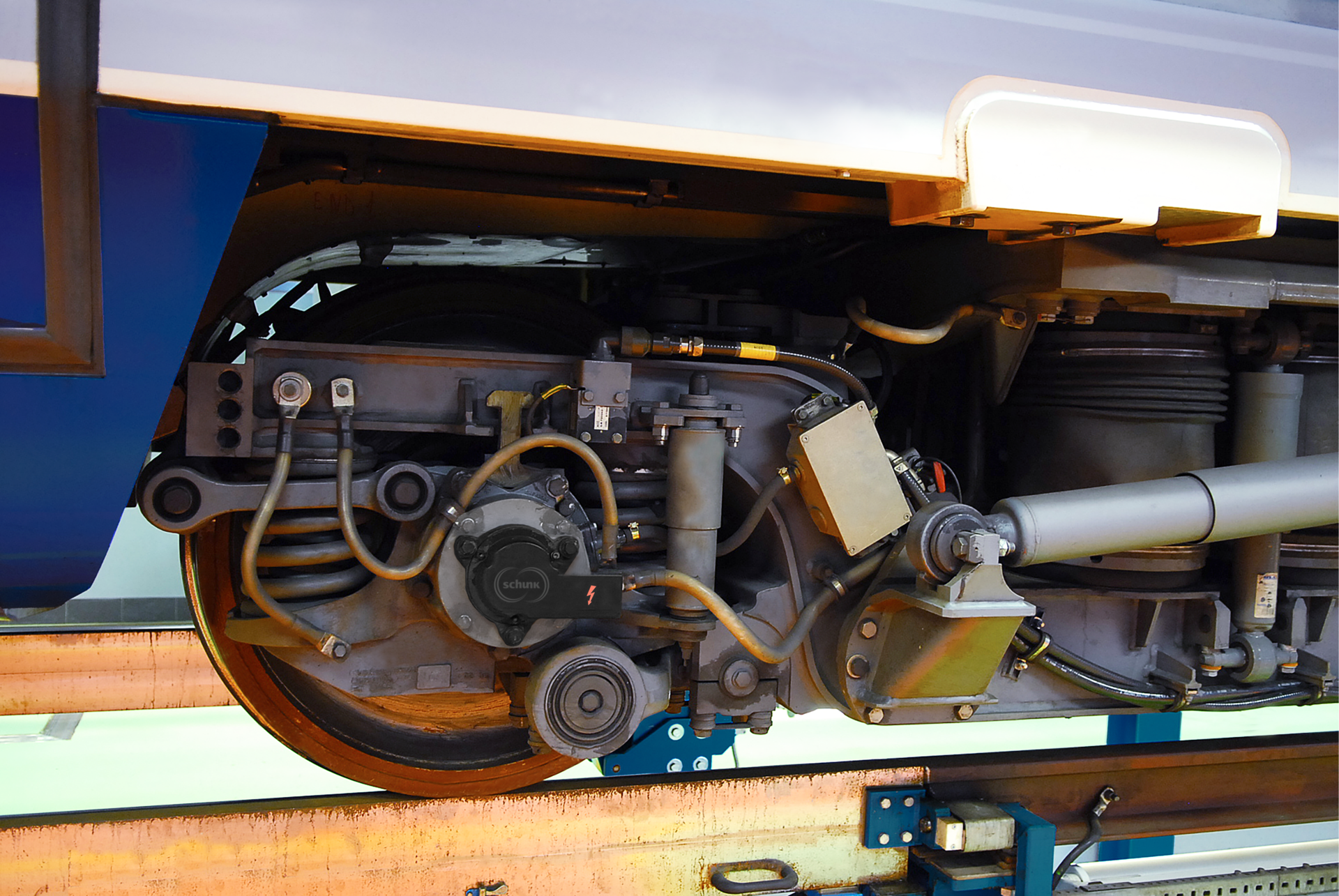

Ultimately, we developed two market-ready shaft grounding systems with carbon fibers (Carbon Fiber Grounding systems) that are suitable for railroad applications and have been tested in accordance with current railroad standards. The difference between the two systems lies in the type of contacting:

- Gear/gearbox-mounted CFG system

This grounding system is mounted near the gearbox. It makes radial contact with the motor shaft with two grounded carbon fibers and dissipates the shaft voltage in this way. The shaft grounding can be tailored to any gearbox or motor and is mounted on the existing interface with little effort.

- Motor-mounted CFG system

This motor-mounted unit makes contact at the center of the axial end of the drive shaft. This contact point is already sufficient to reduce the shaft tension. The system can be fixed on any motor shield.

In addition, we are happy to support our customers when it comes to customized designs of shaft grounding systems. Here, they benefit from our decades of development experience.

This is how Schunk CFG systems work:

Grounding systems: Seven advantages at one blow

Regardless of which system customers choose in the end, they receive a solution which

- dissipates vagrant shaft voltages,

- protects against expensive bearing damage

- is resistant to strong vibrations and

- is insensitive to changes in the direction of rotation,

- is reliable even in the event of water or oil ingress, and

- is generally easy to retrofit.

Best of all, even under the toughest conditions, a typical maintenance interval with a CFG system is 500,000 to 600,000 vehicle kilometers.

How are such long maintenance intervals possible?

Its good electrical conductivity and favorable tribological properties make carbon a very useful material when it comes to power transmission - and thus also to shaft grounding. Because of these properties, carbon fibers and carbon brushes have become the most popular material for shaft grounding.

These properties are further enhanced by the infiltration of our carbon fibers, making Schunk's CFG systems particularly stable and low-wear.

In short, for vehicle manufacturers and transport operators who rely on the performance of their vehicles and want to extend maintenance intervals, shaft grounding systems with carbon fibers are a reliable method of protecting transmission and engine bearings.

Interested in more information? Find all relevant brochures and documents on the topic here.

Download now