The purer, the safer

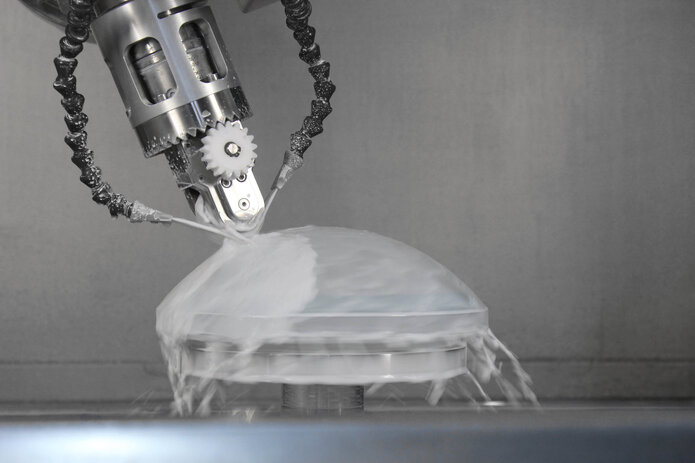

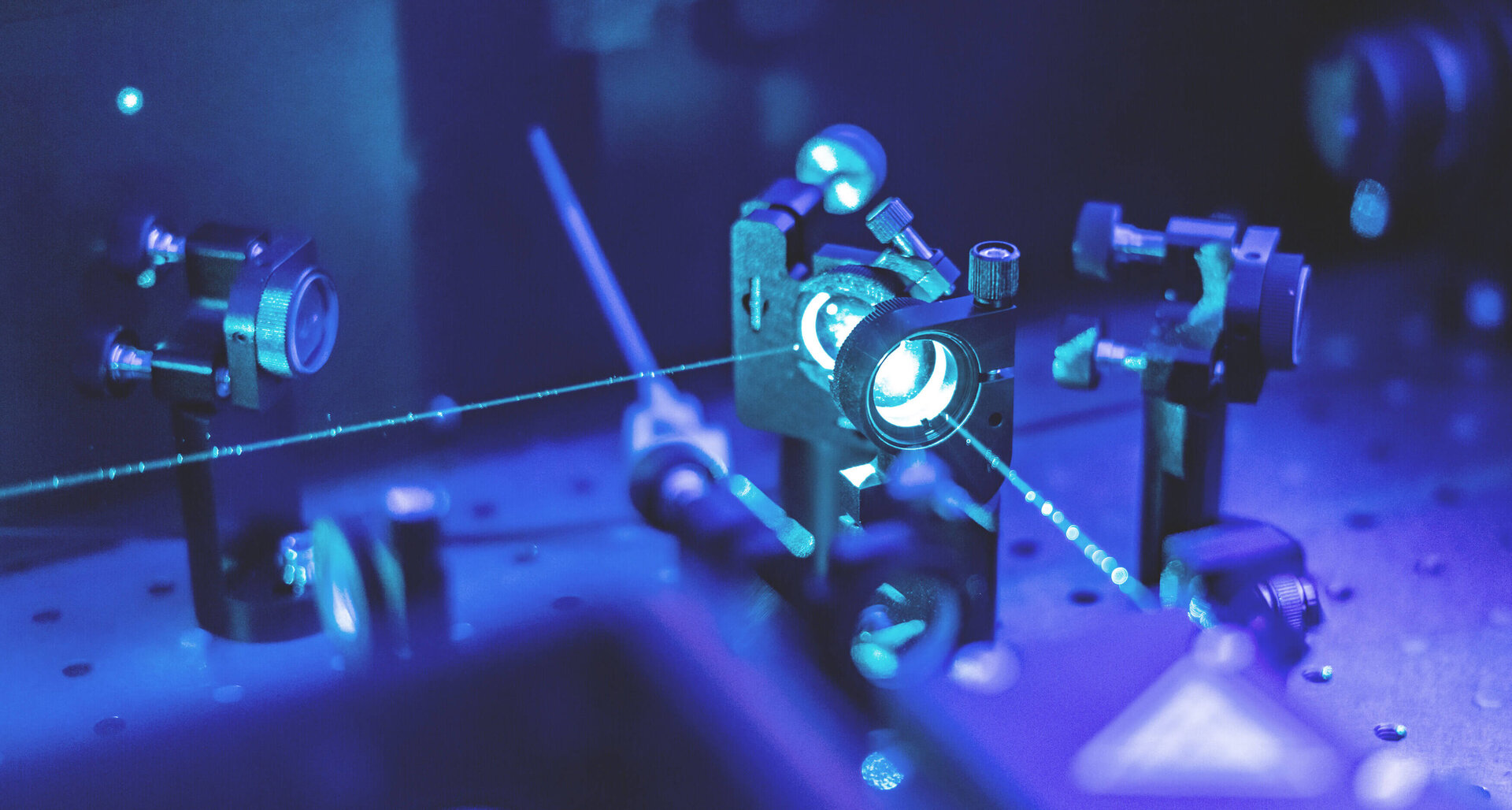

Together with our customers, we work to protect and enhance life. With customized solutions, ultra-pure materials and technical products, we support companies, laboratories and research institutes in achieving these goals safely and sustainably. Because with our solutions they can protect patients and staff in the operating rooms from highly-resistant germs. Or ensure that people, processes and products in pharmaceutical production are safe. When it comes to successfully implementing scientific findings, making your production even safer and sustainably increasing product quality, you can rely on our expertise in materials technology and machine design.