Effectively reduce costs thanks to Schunk OnTrack Monitoring

Defective overhead lines and pantographs are typical problems that can cost a transportation company dearly. This is exactly where Schunk OnTrack Monitoring comes in and offers great financial savings potential. Not only are the costs of delays reduced, but the data collected also simplifies scheduled maintenance. Continuous monitoring during regular rail operations enables potential sources of damage to be detected at an early stage. With short reaction times, costly pantograph or infrastructure damage can be avoided. If damage does occur, the data determined by OnTrack enables objective root cause analysis and targeted repairs to be carried out quickly. Last but not least, unscheduled maintenance such as the repair of damaged vehicles and overhead lines can also be carried out more easily, more quickly and therefore always more cost-effectively by using the system.

Self-sufficient and universal - the OnTrack Monitoring system from Schunk

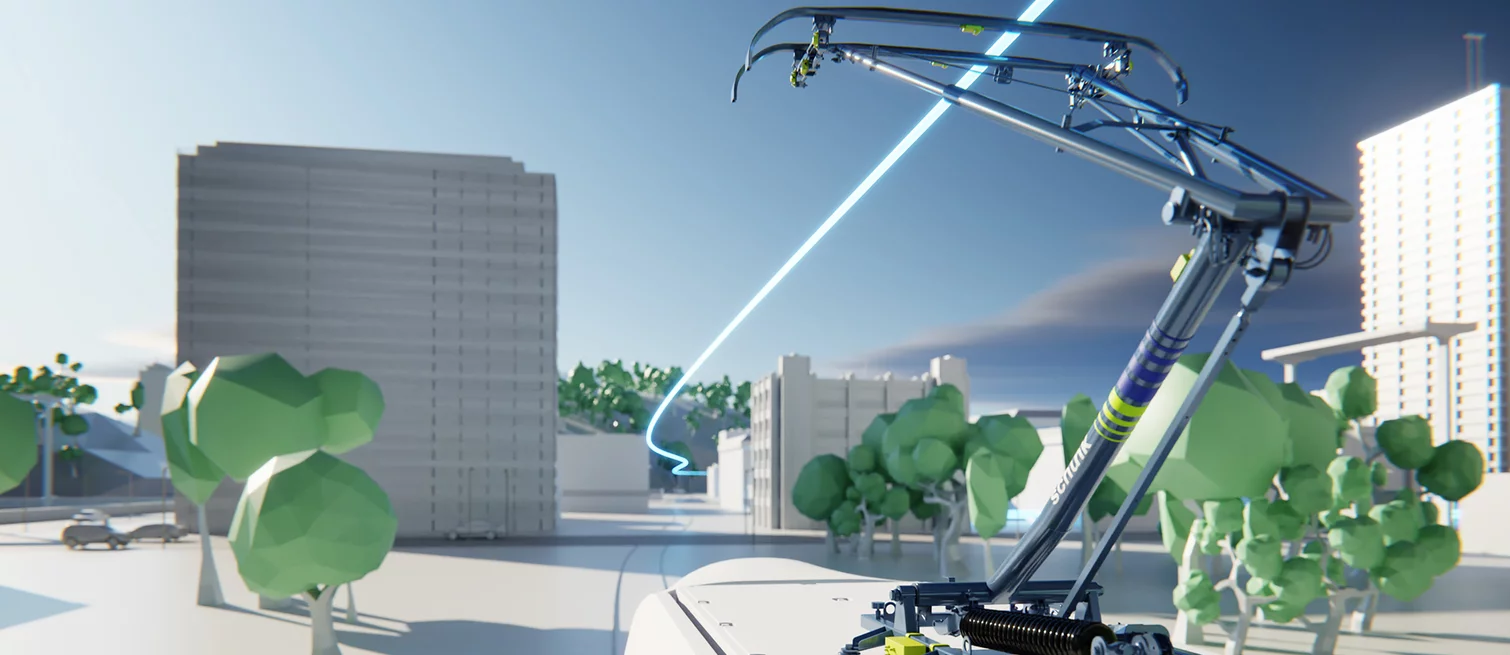

The special feature: with the autonomous system, existing pantographs can be retrofitted, always complying with the applicable railroad standards. An autonomous power supply, high resistance to the environmental influences typical for the application, and a low dead weight create a functional and reliable solution.

Infrastructure and sensor technology - the components of the OnTrack solution

OnTrack Monitoring is made up of various components that interact with each other and make the data-driven system solution possible in the first place. The conventional pantograph is supplemented by various sensors positioned in the areas of the rocker and the base frame. They are able to detect possible faults in the overhead line and the pantograph. The base unit, which is attached to the base frame, ensures the power supply and enables data processing and data transmission via WLAN, GSM and LTE in order to carry out in-depth evaluations quickly and efficiently in the cloud-based database.