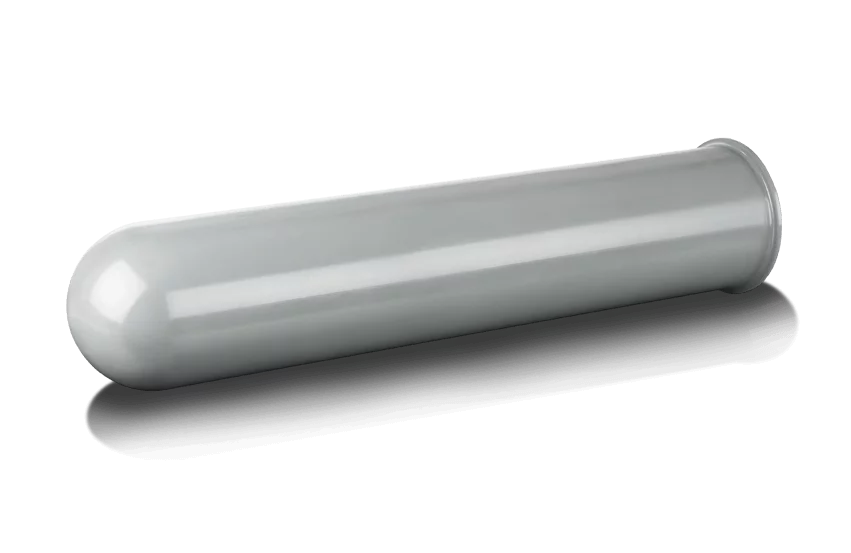

Ceramic Protection Tubes for Furnace Construction

In furnace and plant engineering, ceramic components require high temperature capability while offering maximum dimensional stability and good oxidation and corrosion resistance. Whether as protective tubes in vacuum and sintering furnaces, as sleeves in process plants, in purge blocks of steel ladles or as protection for heating elements - you can always rely on Schunk quality.

Silicon carbide and alumina protection tubes

Manufactured for the Highest Demands

Protection tubes and sleeves made of silicon carbide (CarSIK) or aluminum oxide (AluSIK) are compelling due to their wear resistance, insulating properties, andgood price-performance ratio.

Where are ceramic protection tubes used?

Our tubes are used as protection against mechanical-corrosive damage to the heating elements of aluminum die casting and holding furnaces. Ceramic slotted and multi-hole tubes have proven their worth in the gassing of molten metals. Individually designed and customized sleeves protect metal components in refineries or boilers. Alumina tubes are also used for current-carrying elements in vacuum and sintering furnaces. Our components find special application in heat treatment processes in wire manufacturing - here they serve as protective tubes for guide elements. In many thermal processes ceramic sheathing of the elements is necessary for a functioning temperature control. No matter where and for what they are used, our products always impress with their reliability, dimensional accuracy and quality.

Schunk Technical Ceramics

for Calcination of Cathode Active Materials (CAM)

for Calcination of Cathode Active Materials (CAM)