Special technical properties of advanced ceramics

The ceramic material, SiC and its variants, offers an optimum combination of properties, both thermal and mechanical, to advance the design of innovative kiln furniture as well as complete systems.

In addition to high flexural strength up to the application limit temperature and low mass, the material variants RB-SiC (silicon infiltrated, reaction bonded silicon carbide) and NB-SiC (silicon nitride bonded silicon carbide) have excellent oxidation, corrosion, and thermal shock resistance. RB-SiC can be used at a maximum application temperature of 1,380°C, while NB-SiC, can be used at temperatures of up to 1,470°C.

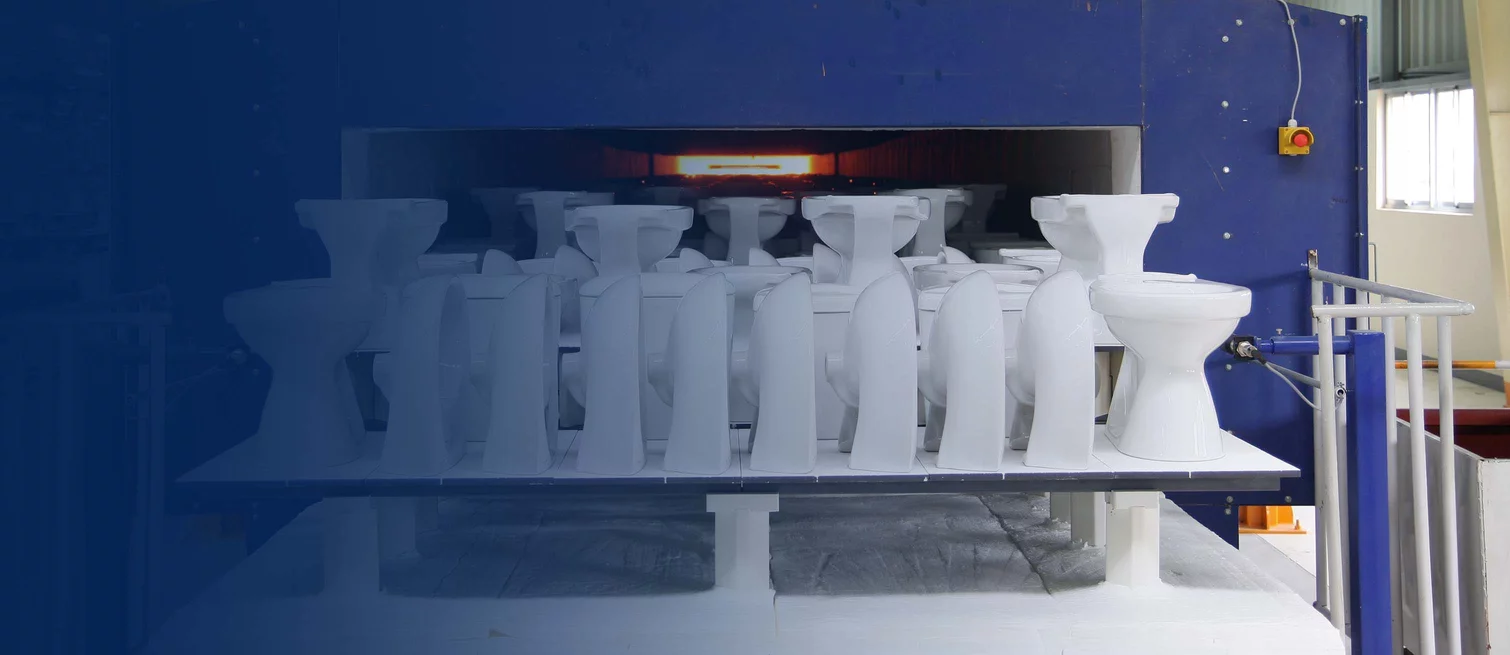

The outstanding materials properties of Schunk RB-SiC materials allow for strong, weight-efficient, dimensionally-stable furnace components effecting the design of innovative firing processes. These innovative firing processes increases firing throughput at lower cost.

Customized solutions from Schunk Technical Ceramics

Schunk Technical Ceramics is a pioneer in the development of RB-SiC materials and manufacturing processes. Schunk RB-SiC and the processes Schunk has developed for its serial manufacture are ideally suited for use as kiln furniture using die casting technology as well as for the world's first series production of large, complex structures using 3D printing (IntrinSiC®).

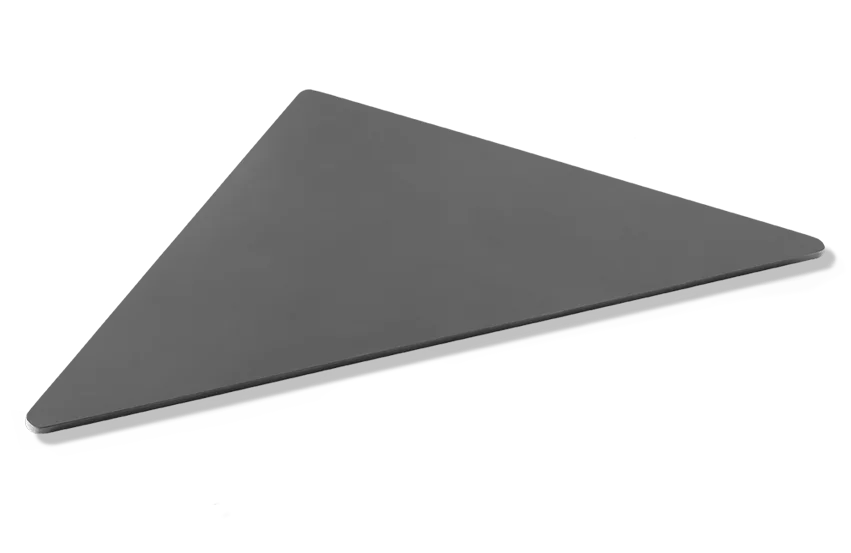

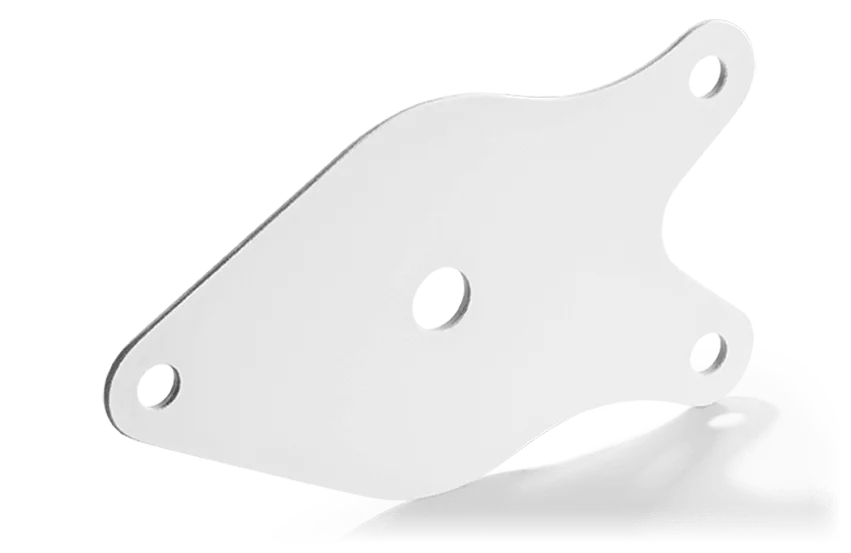

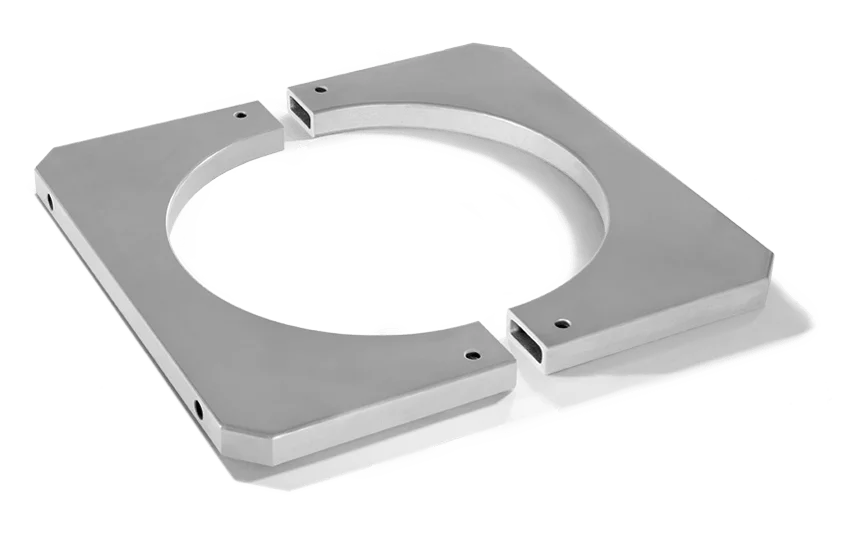

In addition to standardized kiln furniture in the form of beams/profiles, support plates (closed as well as optionally in perforated design), support rollers, setting rings for built-in washstands, plate racks, cassettes and supports, Schunk Ceramics offers complete application- & customer-specific kiln furniture systems in combination with design services that are unique in the market to date.

For the sanitary ceramics market segment, for example, Schunk has a market-leading complete package of weight-optimized RB-SiC beams (Eco-Light®) with up to approx. 40% higher flexural strength compared to commercially available products (including a spectrum of product-accompanying services, among others, 5-year product warranty*, profitability calculation, static load verification, and much more). Additionally included are NB-SiCBore-Grids, which can contribute to reduced defects in sanitary ceramics due to the convective flow and uniform temperature distribution contributing to further cost reductions. The innovative overall package is rounded out by vertical RB-SiC supports (for kiln cars in tunnel kilns and bogie hearth furnaces), which have excellent fatigue strength compared with conventional refractory ceramics with significantly increased product service life and significantly reduced maintenance costs.