Materials used by Schunk Technical Ceramics

Welcome to the Future of the Space Industry

Weight reduction plays a major role in the aerospace industry. We meet this requirement with bionic component optimization - it gives our ceramic components greater rigidity, functionality, dynamics and safety at a low weight. And it also saves on material costs. Thanks to their outstanding material properties, our reaction-bonded silicon carbide ceramics are mainly used in measuring systems, in the construction of satellites and optical systems such as mirrors.

Challenges in the Space Industry

The space industry is facing a number of challenges, including the need to make the development and launch of satellites faster and more cost-efficient. The main requirements include:

- Weight reduction: A critical aspect in space travel, as lower weight leads directly to lower launch costs.

- Increasing reliability: High reliability of satellite systems is crucial to ensure the success of missions.

- Innovative materials: All materials used must be able to withstand the extreme conditions of space.

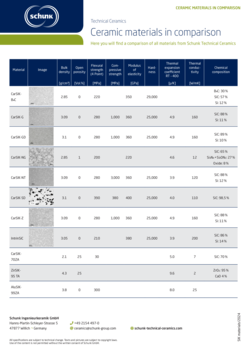

Comparison Chart: Materials

3D printing: a paradigm shift in space travel

The use of 3D-printed technical ceramics in the manufacture of satellite components marks a turning point in the space industry. This technology not only enables a significant reduction in weight and costs, but also opens up new possibilities in the design and production of space systems. With the ability to realize complex geometries and customized designs, 3D printing sets new standards in terms of efficiency and performance of iSatellite systems.

Schunk Ingenieurkeramik: Your partner in aerospace technology

At Schunk Ingenieurkeramik, we fully understand the challenges and opportunities of the space industry. Our expertise in the development and production of technical ceramics, combined with our 3D printing technology IntrinSiC© , makes us the ideal development partner for the satellite components of tomorrow.

Create design in diamond-like hardness